According to the feeding mode, it can be divided into cold feed extruder and hot feed extruder. Hot-fed rubber extruders are mostly used as preform machines or filter rubber equipment in production. The production efficiency of hot-fed Rubber Extruders is usually higher than that of cold-fed rubber extruders.

The advantage of cold feed rubber extruder is that it can continuously feed to ensure the pressure in the screw barrel, so that the constant pressure in production is good. Cold-fed rubber extruders are usually much more expensive than hot-fed rubber extruders. Now cold-feed rubber extruders are mostly used for extrusion and production of finished products. According to the different specifications of extruded rubber, the design of Rubber Extruders is also different.

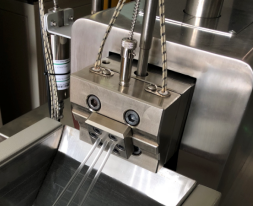

Laboratory extruders are now common silicone rubber extruders, EPDM rubber extruders, dual wrist type conjugate feed Rubber Extruders and other equipment. There are also screw design of different types of rubber treatment equipment, such as exhaust rubber extruder, pin rubber extruder and so on.