The difference between the extruder and the injection molding machine and the use of the extruder:

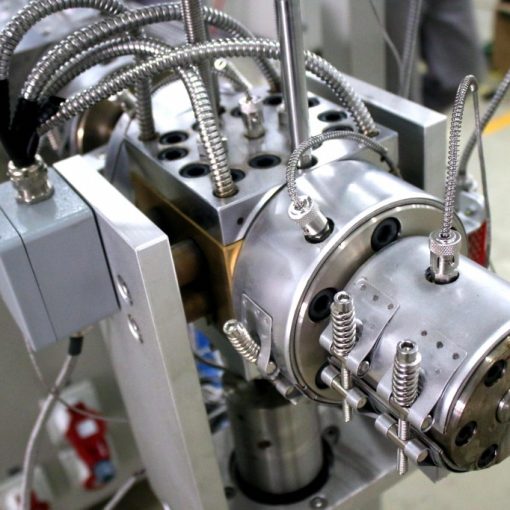

- The extruder, that is, the screw extruder, relies on the pressure and shear force generated by the rotation of the screw, so that the material can be fully plasticized and uniformly mixed, and formed by die molding.

Use of the extruder:

1)Pipe extrusion: suitable for PP-R pipe, PE gas pipe, PEX cross-linked pipe, aluminum-plastic composite pipe, ABS pipe, PVC pipe, HDPE silicon core pipe and various co-extruded composite pipes.

2)sheet and sheet extrusion: suitable for PVC, PET, PS, PP, PC and other profiles and sheet extrusion. Extrusion of other various plastics such as silk, rods, and the like.

3)Extrusion of profile: Adjusting the extruder speed and changing the structure of the extrusion screw can be applied to the production of various plastic profiles such as PVC and polyolefin. Modified granulation: suitable for blending, modifying and reinforcing granulation of various plastics.

Second, the injection molding machine is also known as injection molding machine or injection machine. It is the main molding equipment for thermoplastic or thermosetting plastics using plastic molding dies to make plastic products of various shapes. Divided into vertical, horizontal, all-electric. The injection molding machine heats the plastic and applies a high pressure to the molten plastic to eject it to fill the mold cavity.

- Use of injection molding machine:

The injection molding machine has the ability to shape complex plastic products with complex appearance, precise dimensions or metal inserts. It is widely used in national defense, electromechanical, automotive, transportation, building materials, packaging, agriculture, culture and education. People in all areas of daily life.