The Setting Method and Working Principle of Lab blown Film

Plastic film blowing machine (man-machine integrated panel touch type)

Blown film series

High precision intermittent film blowing system controlled by computer is used to realize precise control by human-machine touch panel to ensure balanced film blowing. The two-layer co-extrusion composite film can prolong the fresh-keeping period of liquid packaging.

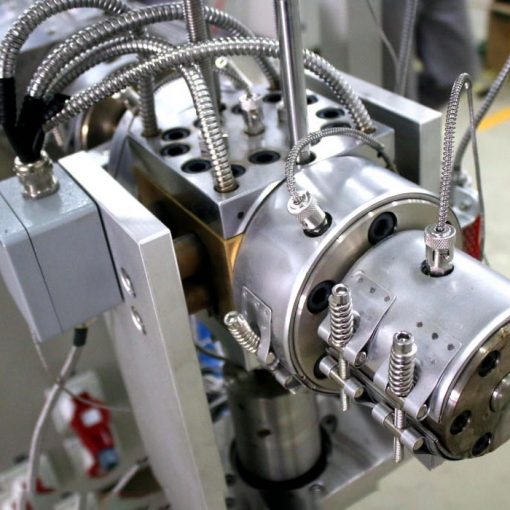

The barrel and screw of the extruder are processed with high quality alloy steel and nitrided to achieve the optimum hardness. The auxiliary machine of the film blower is equipped with a platform-type worktable, which makes the operation convenient and matches the formulation of bubbles.

Special superhard aluminium alloy profiles are selected for the tooth platoon body, and the surface is treated by anodic oxidation, which can realize precise film blowing and concave and convex pressing in high-speed operation. The patented adjusting mechanism perfectly realizes the precision control. The main drive chain of the tooth platoon adopts special chains with relative strength enhancement of about 45%. The precision stability of the machine is improved and the service life is prolonged.

Coiling device: double take-up and double split, its power adopts moment motor, which can maintain appropriate tension, neat take-up and easy change. Imported set of equipment is adopted to improve the stability of the machine, with low noise, high performance and long service life. Imported devices are used to reduce noise and aerodynamic impact.