Definition of hot melt extruder:

The treatment of various polymeric materials above the glass transition temperature makes thermoplastic adhesives or polymers, and active compounds at molecular level, to effectively mix HME applications in the pharmaceutical industry: an effective method to improve solubility of insoluble active drugs.

Possible ways to enhance API bioavailability:

Improve solubility in aqueous media by changing the following properties:

Particle size: Micronized

Crystal structure: conversion to an amorphous structure

Physical Properties : Solubilization, Molecular Dispersion Solution (Liquid or Solid) Nanoparticles

Improve the activity of the active operation system of the intestinal mucosa:

Solubilizer: Modifying transporter activity (Eg:g-pg activity)

Heating melt extrusion technology: solid state solution or solid dispersion dispersed in molecular state.

HME Pharmaceutical Ingredients: polymer or lipid carriers, plasticizers and lubricants, drug release regulators, filling agents, superdisintegrating agents, bioadhesives, antioxidants or antistatic agents,

Active drug components (API) are usually mixed with a variety of auxiliary materials or carriers to form a final drug product. Hot melt extrusion (HME) is a technology to distribute API evenly in a polymer based carrier using a twin screw extruder. In the continuous extrusion process of twin screw extruders, the mixing mechanism and unit operation are complete for the plastic industry and the pharmaceutical industry. The same.FDA encourages continuous processing using PAT initiative.

Advantage:

Continuous process

Less process steps

Solventless

Improvement of biocompatibility of drugs

Sustained release ability

Improved drug solubility

On-line monitoring

Low cost of processing

Design according to production and technical requirements

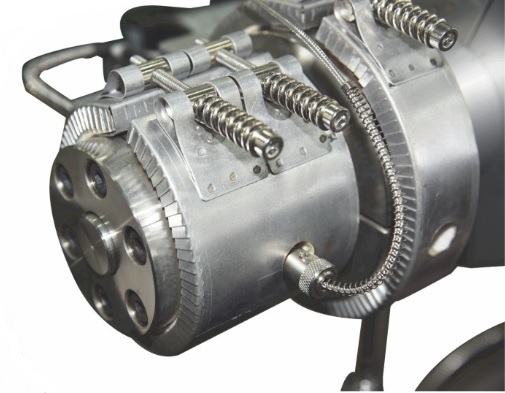

The application of hot-melt extruder in the pharmaceutical field is increasing. Many data show that hot melt extrusion can effectively improve the drug dissolution and bioactivity utilization. We have designed and developed various types of hot melt extrusion with many years of research and experience in the field of extruder. It provides a complete solution for hot melt extrusion application for our customers.