Performance characteristics of lab twin screw extruder:

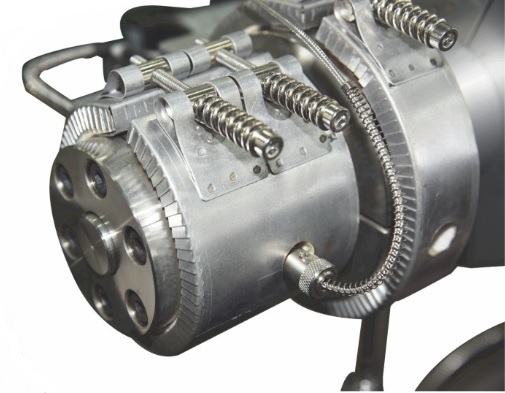

1. The screw and barrel adopt advanced building block design, that is, the screw and barrel are composed of various interchangeable threaded elements and barrels. Therefore, according to different materials, different process requirements can be flexibly combined into an ideal screw configuration, to achieve a multi-purpose machine, a multi-purpose purpose machine, and the worn threaded components and barrels can be replaced locally to reduce maintenance costs.

2. The tooth profile of screw element in small twin-screw extruder is optimized by computer. It has good self-cleaning ability and optimal volume power.

3. The lab twin-screw extruder can be combined with one-stage, two-stage or multi-stage vacuum exhaust structure, which has strong exhaust devolatilization ability and can complete various mixing operations with high devolatilization.

4. The screw element is made of high quality alloy tool steel, and the working surface is hardened to meet the requirements of various blending operations. Nitrided steel barrel can be used for general operation requirements of the user barrel, for wear or corrosive operation requirements of the user barrel can be used bimetal high wear-resistant, corrosion-resistant barrel.

5. The transmission box of deceleration distribution (hereinafter referred to as the transmission box) adopts the structure that integrates deceleration with torque distribution, which is compact and reasonable. The main parameters are optimized and determined, and the reliability is strong. The drive motor is stepless speed regulation by frequency converter. The driving motor and the transmission box are connected by the elastic pin coupling to realize the direct flexible transmission, which can ensure the smooth and safe operation of the equipment.

6. The main engine is equipped with weightless feeding system. The feeding quantity can be adjusted smoothly and continuously, and the production capacity of the unit can be adjusted conveniently within a certain range.

7. according to user requirements, multiple feeding systems can also be configured to meet different production process requirements.

8. The temperature control system of this machine is heated by casting aluminum or copper heater. The heating is fast and the life is long. The cooling is cooled by high-temperature conductive oil without temperature shock. The circulating cooling is carried out.

9. The control system of small twin-screw extruder adopts the programmable computer controller system originally made in Europe. The control temperature adopts PID and fuzzy control algorithm, and the control temperature is accurate. The driving motors of the whole machine can be controlled locally or online, and the operation is convenient, simple and easy to understand, and the interface is beautiful. All operation parameters can be set, modified or displayed by touch screen operation, and has a variety of interlocking protection and alarm functions.

10. The standard configuration of this machine is cold drawing strip pelleting system. According to different operation requirements of customers, it can also be equipped with automatic quick net change, water ring hot cutting, air-cooled hot cutting, side feeding system and other devices.